About

Over sixty years of knowledge working for you

From our emergence in the precast concrete marketplace in 1960 as Smith-Cattleguard, our focus has always been on creating innovative products to solve problems and contribute to the world around us. We started the company with a new idea – a precast concrete cattleguard to keep the cows from roaming on local farms – but the vision of our founder, David G. Smith, and his son, Rodney I. Smith, soon propelled the company in new directions.

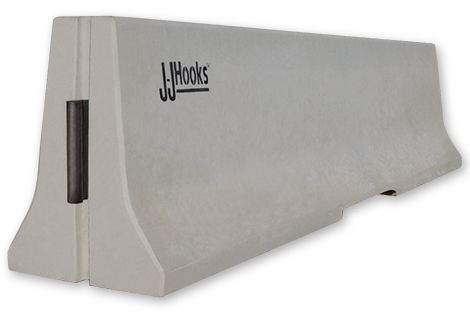

Now in its third generation, Smith-Midland Corporation continues to develop and market industry-changing products, like the J-J Hooks traffic barrier system, our Easi-Set total-precast utility buildings or SlenderWall architectural cladding panels. Through the Easi-Set Worldwide subsidiary, we provide licensing for five innovative product lines to precast manufacturers throughout the world. These groundbreaking systems make Easi-Set the industry’s leading licensor and provide high-quality, profitable product offerings for precasters.

A publicly traded corporation since 1995, Smith-Midland continues to evolve, innovate and enter new markets, adding manufacturing facilities in North Carolina and South Carolina to serve the construction industry. Through another subsidiary, Concrete Safety Systems, we are the leading supplier of rental safety barrier in the Mid-Atlantic region and manage logistics for security barrier installations throughout North America.

While we are known as a major regional precast concrete manufacturer, we think of ourselves as a place where people are developed. We bring together elite engineering, dedicated support staff and a skilled production team in a workplace dedicated to lean manufacturing to satisfy the needs of our customers. At the core of everything is passion for precast and our desire for continuous improvement. Whether it is through our award-winning projects, an ongoing focus on safety, or community involvement, we strive for excellence in all our operations, backed by superior service and a commitment to our Associates and our customers.

Company Video

Patented Products

Research and development has been integral to the Smith-Midland philosophy since our very first day. We designed and patented many of our own products to meet a need or solve a problem for our customers – like the J-J Hooks positive connection safety barrier system. The connection system enables the barriers to slide quickly into place, significantly speeding installation, and making it easier and safer for work crews. Our family of innovative proprietary products:

Family of Companies

Smith-Midland Corporation consists of three precast concrete manufacturing facilities, a product licensing subsidiary, a barrier rental company and an internal advertising/marketing operation.

Smith-Midland

Manufactures thousands of precast concrete products at three plant facilities: Smith-Midland in Midland, VA.; Smith-Carolina, in Reidsville, N.C.; and Smith-Columbia, in Hopkins, S.C. These three strategic locations enable us to serve a significant portion of the Eastern Seaboard – from New York to Atlanta.

Midland Advertising + Design

A full-service advertising and public relations firm.

Leadership Team

Company Culture

Company Culture

Skilled craftsmanship, innovation, and an entrepreneurial spirit have been at the center of the Smith-Midland culture since its founding. Wrapped around those core values is a passion for our people and our customers. We encourage our Associates to learn and grow, and they provide the foundation for our success. At the end of the day, we’re builders, and our goal is to contribute to the world around us by constructing a safer, more resilient world while enriching the lives of our Associates and the communities where we live and do business.

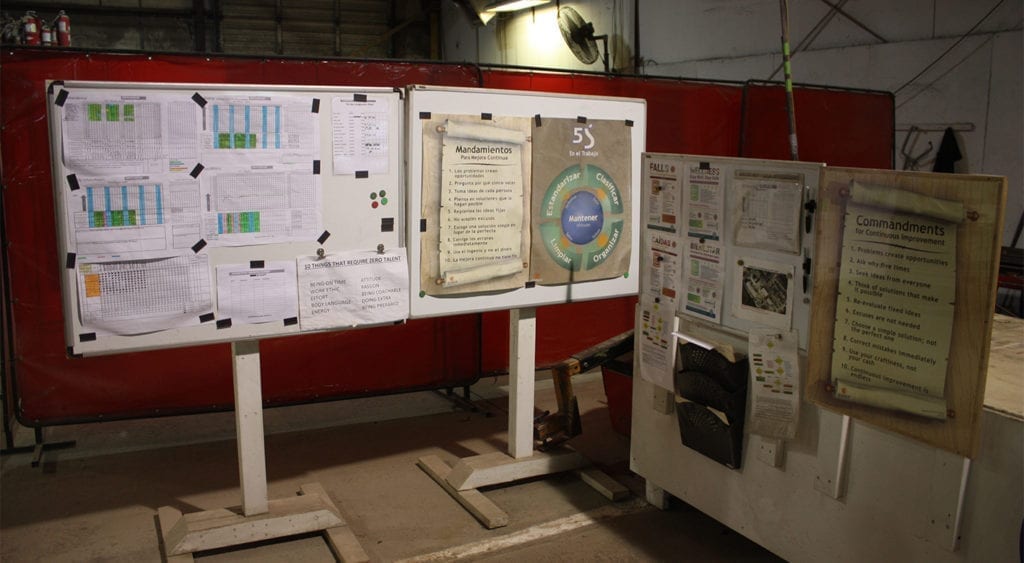

Lean Manufacturing

Lean Manufacturing

Smith-Midland Corporation utilizes lean manufacturing processes and training that emulates the Toyota Production System. That means our goal is to eliminate waste, maintain a clean, well-organized working environment, and reducing inefficient work practices at every opportunity.

We tear down the walls on traditional manufacturing methods and take a more holistic approach to the process of producing precast concrete products. Ultimately, building a better, bigger, and stronger company which, in turn, results in; more value for our customers; more profits for our investors; and a place where our associates can grow and prosper.

Traditional manufacturing focuses all of its attention on how quickly processes can complete a task. It isolates production in each area along the way and emphasizes a top down approach to identifying and correcting problems. This makes it difficult to react quickly when a problem arises. It is a typical and cumbersome approach to manufacturing.

Traditional manufacturing focuses all of its attention on how quickly processes can complete a task. It isolates production in each area along the way and emphasizes a top down approach to identifying and correcting problems. This makes it difficult to react quickly when a problem arises. It is a typical and cumbersome approach to manufacturing.

Smith-Midland is dismantling this model, looking at material as it flows through the process of manufacturing and empowering employees to address and continually improve the issues they encounter.

Safety First

Safety First

As a people-centered company, we keep safety on the frontline of everything we do. As part of our lean manufacturing environment, we eliminate waste, strive for a clean, well-ordered workplace and look for efficiencies in the movement of equipment and people during work processes. That helps to create a safer environment, but that’s only part of our commitment. A full-time safety officer oversees our three manufacturing plants and sets up regular OSHA safety training. Safety huddles start each day and each new project. And the HR/Safety team tracks safety every day and reports to senior management each week. We also have a Safety Observation program, which is a management walk-through to look for ways to improve safety. Our extensive training and expertise in safe working practices carries over to the job site and benefits our customers through the safe working protocols practiced by our installation and delivery crews. Needless to say, we take safety very seriously. All of these programs are designed with one goal in mind: making sure every Associate returns safely home to their family at the end of each day.

Community Involvement

Community Involvement

We are a community-based company. And because most of our Associates have deep roots in the places where we operate, we encourage them to play an active role in supporting local nonprofit organizations, such as the Boys and Girls Club, Habitat for Humanity and the schools, arts associations and service groups where we live and work. Smith-Midland Corporation backs up our commitment with financial support to a variety of nonprofits with a goal of contributing to the health and well-being of our fellow citizens.

Awards

Awards

Our list of award-winning projects is long and spans the decades, but we are most proud of the individuals who make those awards possible. Each award we earn symbolizes the pride in craftsmanship, attention to detail and commitment to excellence that our Associates bring to work every day.

Washington Building Congress Awards

- 2016 Precast Concrete Craftsman Award: Smithsonian National Zoological Park retaining wall

American Concrete Institute Awards

- 2015 Concrete Award: Award of Excellence: Johns Hopkins Nelson/Harvey Building, Baltimore, MD

- 2011 Concrete Award: Concrete Buildings: M Square II building, at M Square Research Park, College Park, MD

- 2010 Concrete Award: Virginia Tech Basketball Practice Center, Blacksburg, VA

- 2010 Concrete Award: Concrete Panels for Route 66, Virginia Highways for LIFE Project

- 2009 Concrete Award: Concrete Buildings/ Special for Jefferson at Inigo’s Crossing in Rockville, MD

- 2006 Judges Award: Creative Use of Project for Jefferson at Logan Circle, Washington, DC

- 2004 Excellence in Concrete Award: Town Square Parking Garage, Silver Spring, MD

- 2003 Creative Use of Project Award: Pentagon Remote Delivery Facility (Retaining Wall)

- 1998 Special Award Category: Award of Excellence for the Spectrum at Reston Town Center

- 1998 Excellence in Precast Concrete Award: The Magellan Buildings, Columbia, MD

- Excellence in Concrete: Wayne Avenue Parking Garage

- 1990 Excellence in Concrete: Sierra Noise Barrier System, I-370 from I-270 West of MD Rte 355

National Association of Industrial and Office Properties (NAIOP)

- 2018 Award of Merit in Mixed-Use Category, Single Building: The Latitude, Arlington. VA

- 2008 Award of Excellence for the Best Building (8-14 stories): 3120 Fairview Parkway Dr, Fairfax, VA

- 2007 Award of Excellence in the Best Building Category for Mid-Rise: Phase I of the Dulles Station Office Building West

- 2007 Award of Merit for the Best Speculative Building R & D: Northridge at Westfield Office Park

- 2004 Award of Excellence for Green Building of the Year: MDOT Headquarters, Hanover, MD

- 2004 Award of Excellence for Build-to-Suit Project: MDOT Headquarters, Hanover, MD

National Precast Concrete Association Awards

- 2025 Standard Work for Continuous Improvement

- 2024 Innovation Award for the App Development for the Quality Technology Improvement Program (QTIP)

- 2021 Best Practices Awards, Second Place

- 2020 Best Practices Awards, First Place & Third Place

- 2013 Creative Use of Precast, Above Ground Category, First Place: The Alexander Luxury Highrise, Edgewater, NJ

- 2013 Creative Use of Precast, Sustainability Awards, First Place: Johns Hopkins Nelson Harvey Building, Baltimore, MD

- 2013 Creative Use of Precast, Above Ground Category, Honorable Mention: Lake Wappapello Restrooms, MO

- 2013 Creative Use of Precast, Below Ground Category, Honorable Mention: Beach Prisms Installation, OceanGate, NJ

- 2012 Creative Use of Precast, Above Ground Category, Honorable Mention: Camp Lejuene Mock Afghan Village

- 2011 Creative Use of Precast, Above Ground Category, Second Place: Virginia Tech Basketball Practice Center, Blacksburg, VA

- 2008 Creative Use of Precast, Above Ground Category, Third Place Award: Combat Training Facility, Virginia Beach, VA

- 2008 Creative Use of Precast, Above Ground Category, Honorable Mention: 3120 Fairview Parkway Dr, Fairfax, VA

- 2007 Creative Use of Precast, Above Ground Category, First Place Award: Jefferson at Inigo’s Crossing in Rockville, MD

- 2006 Creative Use of Precast, Judges’ Award: Beach Prisms, Erosion Control Barriers

- 2005 Creative Use of Precast, Second-Place Award: Jefferson at Logan Circle, Washington, DC

- 2004 Creative Use of Precast, Building Projects Award: Marriott ExecuStay Project, New York City

- 1997 Building and Site Amenities Products: Marymount Medical Centre

Association of General Contractors

- 2023 Washington Contractor Award – Transform I-66 Outside the Beltway

- 2020 Washington Contractor Award Multi-family/Mixed-Use: The Lumen, SlenderWall Architectural Project, Tysons, VA

- 2018 Multi-family/Mixed-Use, Project under $5 million: The Latitude, Arlington. VA

- 2018 Merit Award – Transit/Highway/Bridge: Eisenhower Sound Wall, Alexandria, VA

- 2017 Design-Build Subcontractor, Project $15-30 million: Smithsonian National Zoological Park Retaining Wall

- 2014 Metro Washington – 420 National Business Park – Project contractor under $150 million

- 2012 Metro Washington – Precast Concrete Subcontractor of the Year

Associated Builders and Contractors

- 2022 Central VA EIC for Specialty Concrete for River Tower at Harbors Edge

- 2020 Annual Central Virginia Excellence in Construction Award for Specialty Concrete: Ferguson Enterprises HQ3, SlenderWall Architectural Project, Newport News, VA

- 2020 Annual Metro Washington Excellence in Construction Award for Specialty Concrete: The Lumen, SlenderWall Architectural Project, Tysons, VA

- 2010 Annual Metro Washington Excellence in Construction Award for Specialty Concrete: Concrete Panels for Route 66, Virginia Highways for LIFE Project

- 2009 Annual Metro Washington Excellence in Construction Award for Specialty Concrete: 3120 Fairview Parkway Dr, Fairfax, VA

Maryland State Highway Administration

- Gold Level 1999 National Quality Initiative (NQI) Achievement Award: I-695 widening project

Easi-Set Industries Building Sales Awards

- 2015 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2013 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2012 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2011 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2010 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2009 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2008 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2007 Outstanding Sales Award: Highest Number of Easi-Set and Easi-Span Buildings Sold

- 2006 Outstanding Easi-Set Buildings Sales Award: Highest Sales Volume of Easi-Set Buildings

- 2006 Outstanding Easi-Span Buildings Award: Greatest Number of Easi-Span Buildings Sold

Precast/Prestressed Concrete Institute

- 2010 Design Award Winner for Best Stadium, Arena or Sports Facility: Virginia Tech Basketball Facility

Southeast Building Conference

- 2019 Grand Aurora Award – Best on the Boards Mixed-Use or Multi-Family Project: The Lumen

- 2018 Grand Aurora Award – Best Mixed-Use Project: The Latitude

Architectural Record

- 1999: Product Reports Award

Affiliations and Memberships

National Affiliations

- AIA – American Institute of Architects https://www.aia.org/

- ACI – American Concrete Institute https://www.concrete.org/

- ASTM – American Society for Testing and Materials https://www.astm.org/

- AGC – Associated General Contractors https://www.agc.org/

- ABC – Associated Builders and Contractors https://www.abc.org/

- NAIOP – National Association of Independent Office Properties https://www.naiop.org/

- NPCA – National Precast Concrete Association https://precast.org/

- PCI – Precast/Prestressed Concrete Institute https://www.pci.org/

- USGBC – U.S. Green Building Council https://www.usgbc.org/

State Affiliations

- MTBA – Maryland Transportation Builders and Materials Association https://www.mtbma.org/

- PCAV – Precast Concrete Association of Virginia https://www.precastva.org/

- VTCA – Virginia Transportation Construction Alliance https://www.vtca.org/