Company Profile

Vision / Mission

The Best Company in Town

Our goal is to be the best company in town – in all of our locations. We strive toward that by focusing on our mission and living out our principles every day.

Our Mission

We develop innovative precast solutions that enhance the infrastructure, quality of life and safety for consumers. Our values include safety, innovation, development of our Associates, a work/life balance, integrity, ownership, community, and learning/teaching/coaching.

Our Principles

Respect for people, lead with humility, Kaizen Spirit – “There must be a better way,” focus on process, seek perfection, assure quality at the source, create consistency of purpose, embrace scientific thinking, think systemically, create value for the CUSTOMER.

CEO’s Annual Letter

To All Smith-Midland Stakeholders:

Our Co-Founder

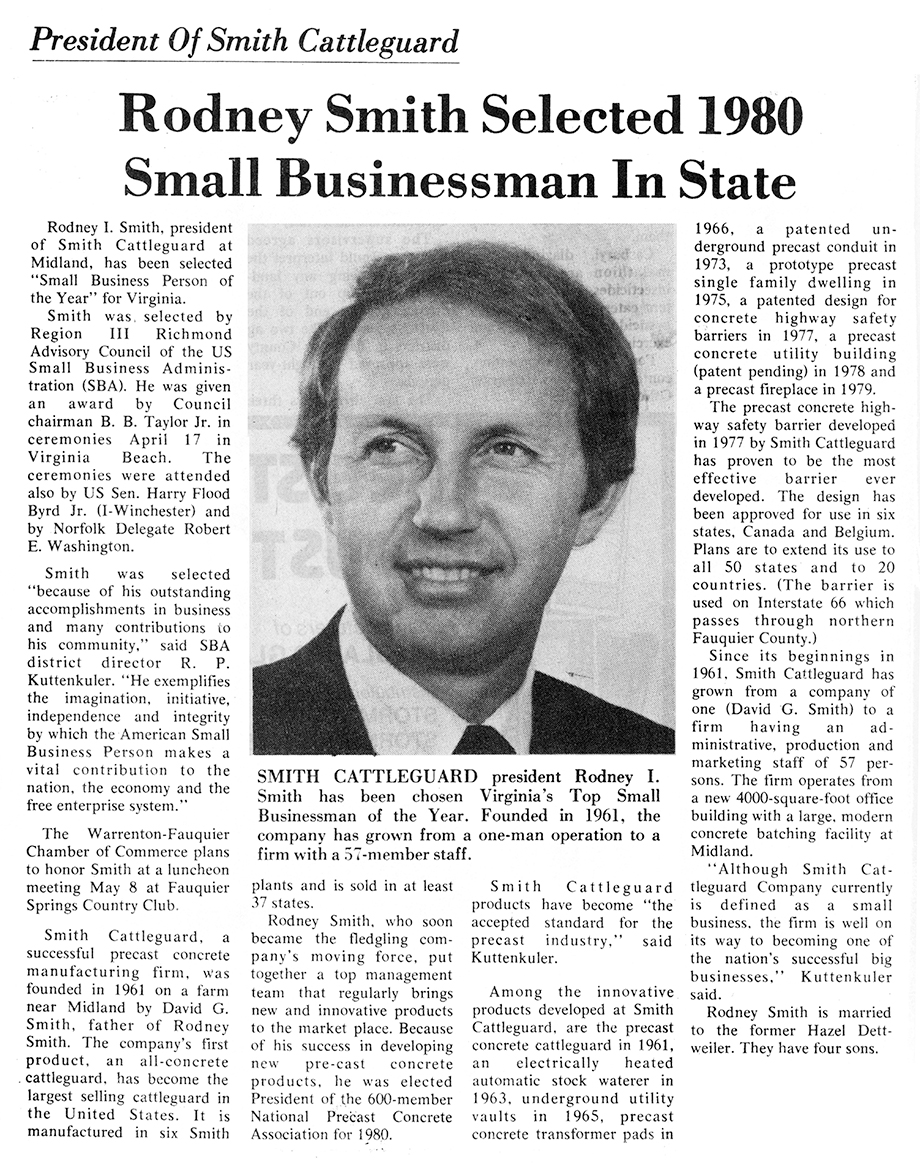

Rodney I. Smith, who, along with his father, David G. Smith, co-founded the company in 1960, retired at the beginning of 2022. Rodney worked at Smith-Midland for 62 years, although I don’t believe that he ever considered it “work”. He was instrumental in developing most of the innovative products and services for which the company is known and licenses to precast concrete producers across the globe. Rodney has been deliberate in providing opportunities for the next generation of Company leaders to develop their abilities, and we’re honored to continue his legacy of developing new products and services, and providing “Excellence in Precast Concrete” to our customers and partners. We thank him for his years of hard work and dedication on behalf of Smith-Midland Corporation.

Record Financial Performance

2024 was a busy year, even by our standards, and another record year for the company with our highest annual revenue and net income. We had many highlights this year due to the hard work, dedication and creativity of everyone at the company and our business partners. We started production in our new plant addition at the Reidsville, North Carolina plant, which doubles the production capacity. Our team completed the installation of our new batch plant and purchased and installed new product forms at our Columbia, South Carolina plant which increases production capacity by 35%. We also had record production of utility vaults at our Midland, Virginia plant, which is tied to increased data center construction in our market.

We purchased bridge forms at a bankruptcy auction, which we disassembled and moved to our Reidsville, North Carolina plant and expect to start production on these forms in 2025. Also at our Reidsville plant, we designed and installed a batch plant for our SoftSound (R) Noise Wall absorptive product. This is the first time we have produced this product outside of our Virginia operation. We also had record service revenue from shipping and installation and record revenue from our core rental barrier fleet with a utilization rate of 75% of the fleet rented. These are only a few of the highlights and show how the Smith-Midland team is executing on our strategic plan and also taking advantage of some of the best tailwinds in our end markets.

We expect our bid activity, sales and production to continue to grow in the foreseeable future, and don’t know of any macro trends that would negatively affect this. We are continuing to invest in new products and production capacity to serve our customers’ needs. We believe our focus and execution will allow us to build on the momentum in our business and position us with multiple strong long-term growth opportunities that will create shareholder value.

Precast Concrete Manufacturing Operations and Product Sales

Precast concrete product revenues for the full year were $45.6 million compared to $38.7 million in the prior year. The increase is primarily associated with increased production at all three plants as a result of increased investment over the past several years. Utility products sales increased by 171% in 2024 compared to 2023, mainly from the increase in dry utility vault production to support the growth in data centers. Easi-Set and Easi-Span buildings and architectural sales increased compared to the prior year. Barrier sales decreased compared to the prior year, in line with the company’s strategic focus to shift from barrier sales to barrier rentals. Even though no SlenderWall production occurred in 2024, there are currently four projects which will start production in 2025.

Service Revenue

Service revenue total $32.9 million for the full year 2024 compared to $20.8 million in the prior year. Shipping and installation revenue increased 48% compared to the prior year, barrier rental income increased 90% year over year and revenue from the company’s core rental fleet increased by 52%. Royalty income hit a record of $3.3 million which was a 24% increase over the prior year. This increase is attributed to the continued replacement of old NCHRP 350 barrier with the JJ-Hooks MASH-TL3 compliant highway barrier and the growth in sales from our newest low profile barrier system.

Macro Environment and Outlook

The company Board, all of our associates and our vendors and service providers work hard to plan for the future and to execute on that plan. I believe the results from 2024 show our ability to deliver results. The worldwide demand for increased infrastructure spending and, more specifically, the increased demand in the markets that we serve, yield positive tailwinds, which we see continuing in the near/midterm. We entered 2025 at our strongest inflection point and I see greater opportunities ahead for Smith-Midland, our clients, employees and our shareholders than at any time in the company’s history.

Smith-Midland Corporation Structure

Founded in 1960, Smith-Midland Corporation is structured in four main divisions: manufacturing, licensing, rentals, and advertising. It is a publicly traded company (SMID) listed on the NASDAQ exchange.

Manufacturing

Smith-Midland’s precast concrete manufacturing reach spans the East Coast from New York to Atlanta, with three strategically located manufacturing plants that define it as a regional market leader in producing commercial, transportation, infrastructure and agricultural products.

- Smith-Midland, founded in 1960, serves as the corporate headquarters and flagship manufacturing plant from its base in Midland, Virginia.

- Smith-Carolina, opened in 1979 to cover North Carolina and the surrounding region, has recently constructed a new plant, giving it expanded capacity to meet growing market demand.

- Smith-Columbia, located in Hopkins, South Carolina, continued the company’s expansion, opening a large manufacturing facility in 2016.

Smith-Midland’s manufacturing plants are nationally certified by the Precast/Prestressed Concrete Institute and National Precast Concrete Association. Together, these three manufacturing plants produce a vast suite of precast concrete products, such as:

- Precast Buildings, prefabricated in the plant and transported to the site, including Easi-Set, Easi-Span, HazMat Models and Restroom Buildings.

- Architectural Precast, including our revolutionary SlenderWall modular building panels and traditional architectural precast panel systems.

- Custom Transportation products, such as SoftSound Absorptive Sound Wall , J-J Hooks Barrier, Post and Panel Sound Wall, Retaining Walls, and Parkway Stonewall.

- Utility Products, including a complete line of vaults and manholes for underground infrastructure, junction boxes and pad mounts.

- Erosion Control, protecting the shoreline with Beach Prisms, a proprietary precast concrete breakwater structure.

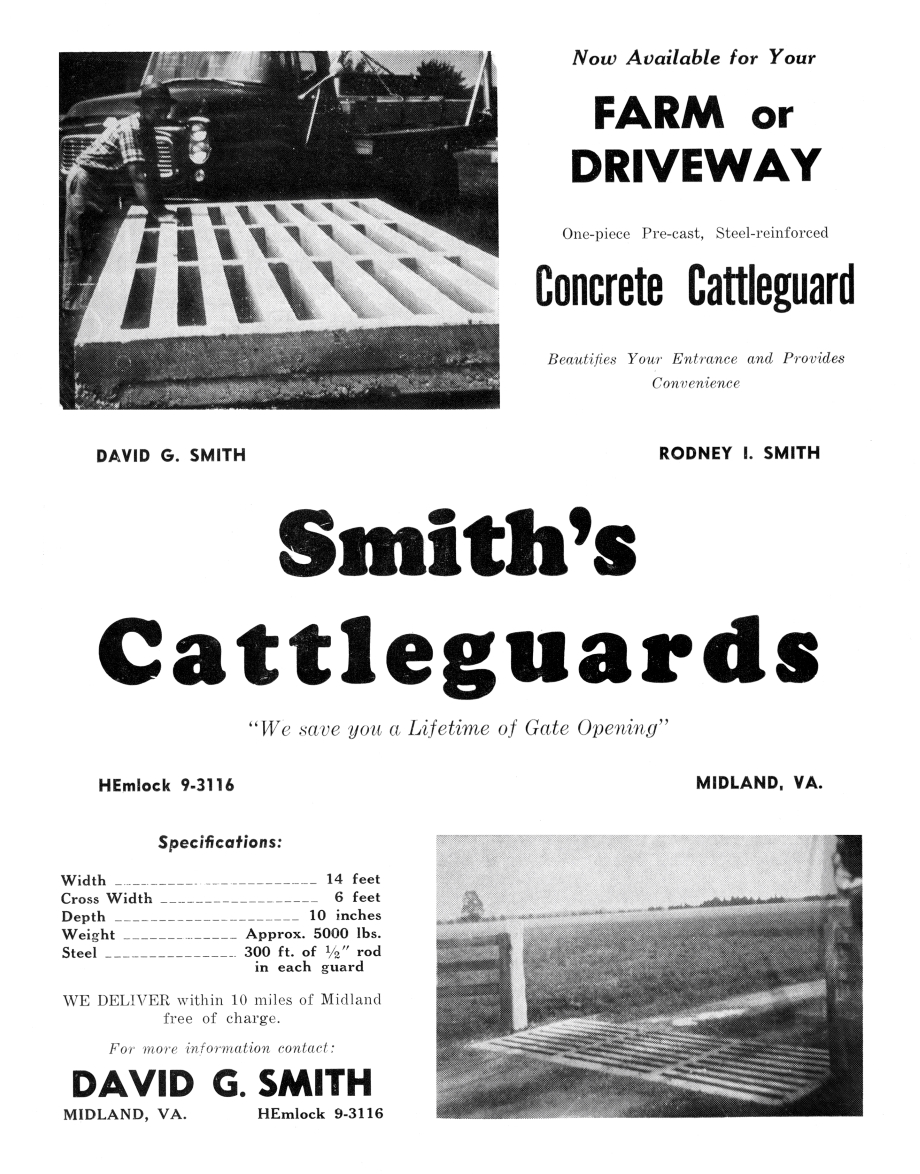

- Legacy Products, such as the Smith-Cattleguard, and wash racks.

Licensing

The company’s active research and development effort has led to groundbreaking new precast concrete products that Smith-Midland patents and licenses through its Easi-Set Worldwide division. These five proprietary product lines are among the most successful in the precast concrete industry and are licensed to qualified manufacturers in North America and in several other countries throughout the world.

- Easi-Set and Easi-Span Buildings, a suite of all-precast utility buildings, completely fabricated in the plant and transported to the site.

- J-J Hooks Security Barriers, the barrier that revolutionized the industry with its simple, effective connection system that speeds installation and improves safety.

- SlenderWall architectural precast concrete steel stud building panels, a cost-effective exterior cladding system for medium-to-large commercial, institutional and multi-family buildings.

- SoftSound precast concrete sound walls, featuring sound absorptive technology with nearly unlimited aesthetic possibilities through the use of color and intricately textured form liners.

- Beach Prisms, a permeable precast concrete wave attenuation structure for shoreline protection and renewal.

Barrier Rentals

Concrete Safety Systems is the leading precast concrete barrier rental service in the Mid-Atlantic region. A subsidiary of Smith-Midland, CSS rents MASH TL3 and NCHRP-35 crash tested barriers for road work, and security barriers for crowd control at special events. CSS rentals include a variety of value-added options and feature a one-call-does-it-all philosophy of handling every step of the rental process from beginning to end, including delivery, installation, relocation (if needed) and pick-up. CSS crews also handle logistics for major barrier installations throughout North America.

Advertising Agency

Midland Advertising + Design is the company’s in-house advertising agency servicing all subsidiaries and two national licensed producer advertising co-ops (SlenderWall and Easi-Set Buildings) with graphic design, web design, media buying and public relations.

1960s

- 1960 – David G. Smith built the first concrete cattleguard for his father-in-law because he was tired of having to open and close the gate. The new product development caught on with the neighbors, who placed orders. Smith formed Smith-Cattleguard Co. with his son Rodney. The business started out as supplemental income to the 95-acre family farm, with the Smiths as the only employees. They invested in a cattleguard delivery truck and advertisements in the local farming journals. Twelve cattleguards were sold their first year. Read Article

- 1961 – Business increased to 60 cattleguards sold in a year’s time.

- 1963 – An electrically heated automatic stock waterer was developed to supplement the cattleguard sales. The new product was a success.

- 1964 – The Smith-Cattleguard Co. had so much business that the Smiths hired full time employees. The cattleguards were sold in seven states at this time. Cattleguards were now produced in metal forms instead of wood, which greatly improved production time.

- 1965 – The Virginia Electric Power Co. asked the Smith-Cattleguard Co. to make a concrete utility manhole for them, which was traditionally done using masonry. The concrete manhole caught on and other concrete utility products were added shortly thereafter. The newly developed concrete fence was also added to the existing product lines.

- 1966 – Centerline and fenceline concrete feedbunks were introduced to the farm products lines.

- 1967 – Smith-Cattleguard’s innovations continued with the development of a concrete trash incinerator. Read Article

- 1968 – The array of products had grown so extensive, that the first farm products brochure was published.

1970s

- 1970 – Smith-Cattleguard Co. had outgrown it’s first plant. The company relocated to it’s current location on Route 28 and built a 10,000 square foot plant. They were able to batch their own concrete in the new plant, whereas previously they’d used ready-mix concrete. By this time the company had 20 employees. Read Article

- 1971 – David Smith retired, but visited the plant occasionally. Rodney Smith took over as president. Smith-Cattleguard Co. opened two franchise plants in Lexington, KY and Gainesville, GA. Utility products had become an important part of the business. New additional product lines included concrete bases, parking curb stones, patio and walk blocks, and production millstones. The company also joined the NPCA.

- 1972 – Highway barriers were added and provided to the Whitehurst Freeway project in Washington, D.C. This contract was the largest in the history of the company up to this date. Planters, subway beams, and stairways for townhomes were also added. Read Barrier Article, Read Company Article

- 1973 – The business continued to grow and the manufacturing plant was expanded by 64,000 feet, primarily for storage. A patented underground precast conduit was added. Farm products franchises also grew. Read Article

- 1974 – Rodney Smith was elected to the board of director’s of the National Precast Concrete Association (NPCA). Read Article

- 1975 – The precast home was developed in response to a lack of adequate housing in the area. Read Article

- 1976 – Highway safety barrier’s tongue-and-groove design was patented.

- 1976 – The state of Virginia accepted Smith-Cattleguard’s newly designed concrete highway safety barrier for construction sites. The tongue-and-groove design replaced the wooden barriers traditionally used. The company also began renting their barrier for use on temporary installations. Business had grown to a point that the facilities needed to be expanded to include a newly constructed office building. Concrete Safety Systems was formed to rent the newly designed safety barriers for construction projects. Read Article

- 1978 – The Easi-Set precast concrete building was developed and patented. The building was originally designed for use as storage, utility applications, and garage space. Easi-Set Industries was formed, with Moffette Tharpe as president and co-founder. The company’s purpose was to offer diversification to precasters under a license agreement. The company began using Smith-Cattleguard developed products. Easi-Set’s roots began with the farm products franchises sold in 1971. Read Buildings Article, Read Easi-Set Article

- 1979 – Rodney Smith was elected president of the NPCA. Smith-Cattleguard of North Carolina opened in order to keep up with rising demand for the company’s products. Precast fireplace designs were purchased from Sierra Precast and added to existing product lines at Smith-Cattleguard and Easi-Set.

1980s

- 1980 – Rodney Smith was named “Small business Person of the Year” for Virginia by the US Small Business Administration. Ad Design was formed to oversee the co-op advertising programs created for the network of Easi-Set Industries’ licensed producers. Read Rodney Article, Read Company Article

- 1981 – The Sierra Wall post-and-panel sound wall system was purchased from Sierra Precast and added to Smith-Cattleguard and Easi-Set. The system was later redesigned due to changing state regulations, resulting in a generic sound wall design.

- 1982 – The Liberty Bank in Warrenton, VA was erected using the first architectural precast produced by Smith-Cattleguard Co. The Horizon crop/manure storage system was developed.

- 1985 – Smith-Cattleguard Co. was renamed Smith-Midland Corporation to reflect the diversity of products now offered by the company. Smith-Midland provided tongue-and-groove barrier to their first presidential inauguration.

- 1987 – Ad Design was reformed under the name Ad Ventures.

- 1988 – The Easi-Brick finish was developed for use on the Easi-Set buildings.

- 1989 – Smith-Midland Corp. (VA) earned plant certification from the NPCA. SMC was the one of the first 14 plants to earn certification. Smith-Midland Corp. (VA) produced architectural precast panels for the National Rifle Association headquarters in Northern Virginia. This project was the first large scale building using SMC’s architectural precast. Easi-Set hazardous materials storage buildings were developed. The first Smith-Midland installation of Beach Prisms test sites occurred following the purchase of the existing technology. The orignial design was improved in the early ’90s. SMC provides highway safety barrier rental to the presidential inauguration.

1990s

- 1990 – Smith-Cattleguard of North Carolina changed its name to Smith-Carolina Corporation to reflect the diversity of their current products. The J-J Hooks highway barrier connection system was developed. It replaced the original tongue-and-groove design.

- 1992 – Easi-Span Clear Span buildings were first developed. SlenderWall architectural precast/steel stud building panels were developed. The first SlenderWall project, the Health Insurance Plan Building in North Brunswick, NJ, was completed.

- 1993 – J-J Hooks barriers are provided to the presidential inauguration for the first time.

- 1995 – Smith-Midland Corporation went public. Smith-Midland (DE) and Smith-Midland (VA) became two separate entities. Smith-Midland (DE) was incorporated in Delaware and became the holding company for Smith-Midland ( the manufacturing plant in Virginia), Smith-Carolina, Easi-Set Industries, Concrete Safety Systems, and Ad Ventures. Read Article

- 1997 – J-J Hooks barrier was provided to the presidential inauguration.

- 1998 – Smith-Midland Corporation received two ACI awards: Special Award Category – Award of Excellence for the Spectrum at Reston Town Center; Excellence in Precast Concrete Award – Magellan Buildings, Columbia, MD. Easi-Cast buildings were developed. The walls and floor of the Easi-Cast building were produced in one monolithic pour. SMC provided SlenderWall panels to the Woodlands I project in Columbia, MD. This was the first project that made use of the newly developed Second Nature (Architectural Precast Concrete Brick).

2000s

- 2000 – SlenderWall panels were used at Times Square, for the 42nd Street renovation project. This was the first project approved by the New York Historical Society for Second Nature (Architectural Precast Concrete Brick).

- 2001 – J-J Hooks barrier was provided to the presidential inauguration.

- 2002 – The Single Outback restroom was developed, expanding the Easi-Set Buildings product line.

- 2003 – Smith-Midland Corp received the NPCA’s Creative Use of Project Award: Pentagon Remote Delivery Facility (Retaining Wall). SlenderWall panels were used on the first high rise project, the Marriott ExecuStay on Third Avenue in New York, NY.

- 2004 – Smith-Midland Corp received the following awards: NAIOP’s Award of Excellence for Green Building of the Year for MDOT Headquarters, Hanover, MD; NAIOP’s Award of Excellence for Build-to-Suit Project for MDOT Headquarters, Hanover, MD; NPCA’s Creative Use of Precast, Building Projects Award for Marriott ExecuStay Project, New York City; ACI’s Excellence in Concrete Award for Town Square Parking Garage, Silver Spring, MD.

- 2005 – The Easi-Set building’s pitched roof design was developed, as well as the Double Outback restroom. Smith-Midland received NPCA’s Creative Use of Precast, Second-Place Award for the Jefferson at Logan Circle, Washington, D.C. J-J Hooks barriers were provided for the Republican National Convention, the World Bank, as well as the presidential inauguration.

- 2005 – Smith-Midland Corp received the following awards: ACI’s Judges Award – Creative Use of Project for Jefferson at Logan Circle, Washington, D.C.; NPCA Creative Use of Precast, Judges’ Award for Beach Prisms, Erosion Control Barriers. Beach Prisms were reintroduced to the market after years of product testing.

- 2006 – Smith-Midland Corp received the following awards: ACI’s Judges Award – Creative Use of Project for Jefferson at Logan Circle, Washington, D.C.; NPCA Creative Use of Precast, Judges’ Award for Beach Prisms, Erosion Control Barriers. Beach Prisms were reintroduced to the market after years of product testing.

- 2007 – Smith-Midland Corp received the following awards: NPCA’s Creative Use of Precast, Above Ground Category, First Place Award for Jefferson at Inigo’s Crossing in Rockville, MD; NAIOP’s Award of Merit for the Best Speculative Building R & D for Northridge at Westfield Office Park; NAIOP’s Award of Excellence in the Best Building Category for Mid-Rise for Phase I of the Dulles Station Office Building West. SlenderWall panels were utilized on the tallest building in the state of Virginia, the Westin Hotel and Luxury Residences in Virginia Beach. Eight Easi-Set Buildings were used as cheetah enclosures by the Smithsonian.

- 2008 – Ashley Smith became President and COO of Smith-Midland (VA). Rodney Smith remained the CEO. The Easi-Span Skyline restroom models were introduced. Smith-Midland Corp received the following awards: NAIOP’s Award of Excellence for the Best Building (8-14 stories) for 3120 Fairview Parkway Dr, Fairfax, VA; NPCA Creative Use of Precast, Above Ground Category, Third Place Award for Combat Training Facility, Virginia Beach, VA; NPCA Creative Use of Precast, Above Ground Category, Honorable Mention for 3120 Fairview Parkway Dr, Fairfax, VA. A continuous improvement program was initiated to implement new lean manufacturing techniques. SoftSound SoundWall, a sound absorptive system, was introduced.

- 2009 – Smith-Midland Corp (VA) received ACI’s Concrete Award, Concrete Buildings/ Special for Jefferson at Inigo’s Crossing in Rockville, MD. J-J Hooks barrier was provided to the presidential inauguration. Smith-Midland Corp (VA) provided revolutionary precast roadway slabs to the I-66 Highways for LIFE project.

2010s

- 2010 – Smith-Midland Celebrates it’s 50th Anniversary. Smith-Midland wins Precast/Prestressed Concrete Institute award for Virginia Tech Basketball facility Architectural Precast project.

- 2011 – Federal Goverment Services Administration approves SMC for Easi-Set Buildings Advantage contract.

- 2012 – Successful invention and test demonstration of Sierra Wall II post-and-panel sound wall system. Concrete Safety Systems provides logistic services for security barrier implementation at the NATO Summit in Chicago. Next generation J-J Hooks MASH level 3 bolt-down, pin-down barrier developed, crash tested and installed on first bridge project. Easi-Set licensed producers surpass the 1,000,000 sq. ft. milestone of SoftSound absorptive sound wall production. CSS contracts for deployment of safety barrier systems at both the RNC and DNC national conventions.

- 2013 – ETS SlenderWall project in Montreal by licensed producer BPDL is first with factory installed windows and insulation, wins prestigious PCI award. Smith-Midland Virginia plant achieves ABC safety award Gold status.

- 2014 – First installation of proprietary H2Out advanced rainscreen caulking system on Johns Hopkins hospital project. SMC receives 1st Place award in annual National Precast Concrete Association CUP competition for the Edgewater, NJ SlenderWall project “The Alexander.” J-J Hooks production for reaches 12,000,000 linear feet milestone worldwide. Enough to reach across the United States from Washington, DC to Los Angeles. Concrete Safety Systems expands its barrier rental service centers to eight locations across the mid-Atlantic. Concrete Safety Systems supplies J-J Hooks barrier for the US/Africa Summit in Washington, D.C.

- 2015 – Smith-Midland completes custom designed retaining wall project for Smithsonian National Zoo in Washington, D.C. Smith-Midland contracts $4 million deal with Dulles Metro Rail expansion. Johns Hopkins SlenderWall project receives American Concrete Institute Award. Smith-Midland Corporation announces stocks move to premier OTCQX Best securities marketplace.

- 2016 – Third precast plant is added in South Carolina, Smith-Columbia. SlenderWall architectural panels chosen for Landmark Tysons Corner project. J-J Hooks freestanding precast concrete safety barrier now MASH TL-3-compliant. 300,000 sq. ft. of SoftSound noise walls to be installed on 2 major Virginia DOT projects. Smith-Midland achieves Gold Status in ABC Safety Award Program. Smith-Midland becomes an OTCQX Best 50 Company.

- 2017 – CSS supplies J-J Hooks security barrier for presidential inauguration in Washington D.C. CSS largest project to date, 39,000 LF of J-J Hooks Barrier will be rented for a $105 million I-81 Corridor MD/WVDOT project. Smith-Midland contracted to produce over 23 Miles of J-J Hooks Safety Barrier for I-395 express lanes in Northern Virginia. SMC President Ashley Smith appointed Chair of National Precast Concrete Association. Smith-Midland wins AGC of DC award for Smithsonian National Zoo wall project. J-J Hooks Freestanding precast concrete safety barrier tested fully MASH TL3-compliant. Smith-Midland announced an OTCQX Best 50 Company for second year.

- 2018 – Smith-Midland wins $9 million J-J Hooks safety barrier contract for I-66 Express Lanes Project. Smith-Midland wins $3.2 million I-395 SoftSound project in Northern Virginia. Smith-Midland signs largest contract in company’s history, 900,000 square feet of SoftSound noise absorptive precast concrete sound wall panels for the I-66 Outside the Beltway Express Lanes project in Northern Virginia. Smith-Carolina Plant Announces new location and major expansion. Ashley B. Smith elected as Smith-Midland Chief Executive Officer. Smith-Columbia plant gains PCI Certification. Smith-Midland adds Global Executive Russell Bruner (former CEO and President of Maersk Line) to its Board of Directors. Smith-Midland achieves Gold Status in ABC Safety Award Program. J-J Hooks production reaches 14,000,000 linear feet milestone worldwide. Precast powerhouse Wells Concrete added as newest Easi-Set SlenderWall licensed producer.

- 2019 – Smith-Midland lands largest SlenderWall project ever produced and the company’s largest contract in its history, 800 Harbor Boulevard project at Lincoln Harbor in Weehawken, NJ. Smith-Midland provides secure permanent barrier for White House perimeter security project. Smith-Carolina opens new manufacturing facility. Smith-Midland makes it an OTCQX Top 50 three-peat.

2020s

- 2020 – Smith-Midland takes 1st and 3rd place in NPCA Best Practices awards. Smith-Midland project selected ENR Project of the Year finalist. J-J Hooks production reaches 15,000,000 linear feet milestone worldwide. Smith-Midland stock SMID is listed on the NASDAQ Captial Market.

Board of Directors

Ashley B. Smith

Chairman of the Board, President & CEO

Ashley Smith is the current President/CEO of the parent corporation and President/COO of Smith-Midland (VA). Previously he served as Vice President of Sales for Smith-Midland (VA) and Managing Director of Easi-Set Industries. He has also served as Vice President of Smith-Midland Corporation (DE) since 1990 and as a Director since 1994. He was named President/COO in 2008 and President/CEO in 2019. As the CEO, he provides strategic vision for the company, while serving as a member of the Board of Directors. Ashley is a past chairman of the National Precast Concrete Association, is a current member of the Board of Trustees of Bridgewater College. He serves as a volunteer leader with many civic, educational and charity organizations.

“Our goal is to develop our Associates to their fullest potential, so they can contribute to their families, to society, and specifically in our company, to produce innovative, high quality, safe and cost-effective products for our customers. For our shareholders, the better we are at these initiatives, the better the results for their investment in Smith-Midland.”

Dominic L. Hunter

Secretary/Treasurer

Dominic brings over 20 years of financial leadership experience to Smith-Midland, with a strong track record in strategic financial planning and operational excellence across a wide range of organizations—including a multinational public company, privately held firms, non-profits, and startups. His executive experience includes leadership as Vice President at SRA International, a $1.7B publicly traded government contractor in Fairfax, VA. His deep manufacturing acumen led multi-year growth as CFO of O’Gara-Hess & Eisenhardt Armoring Company, a U.S. military contractor with a rich history that includes manufacturing armored vehicles for Presidents Kennedy, Reagan, Clinton and Bush, the Department of Defense and the Department of State. He is a graduate of the University of Virginia McIntire School of Commerce and holds an active license as a Certified Public Accountant.

“I look forward to partnering with the talented team to build upon the company’s long-standing legacy and strong foundation. Together we will work to unlock new growth opportunities, accelerate financial performance, and drive continued value creation for our customers, employees and shareholders.”

“A hallmark of Smith-Midland has always been our commitment to producing high quality products backed with a high level of service. Today, we are still as committed to those standards as ever.”

Read Van de Water

Director

Ms. Van de Water is the Senior Vice President, External Affairs at Safran USA, an international high-technology aerospace, defense, and space company. Prior to taking on her current role at Safran USA, she served as the Chairman and member of The National Mediation Board from 2003 to 2009. Ms. Van de Water served as the Assistant Secretary for Aviation and International Affairs for the U.S. Department of Transportation from 2001 to 2003 and as Legislative Counsel of International Trade and Health Care for The Business Roundtable from 1997 to 2001. Ms. Van de Water received her J.D. from The Georgetown University Law Center and is also a graduate of Elliott School of International Affairs at George Washington University, and The University of the South: Sewanee.

“I am honored to be welcomed as a new board member of Smith-Midland,” said Ms. Van de Water. “I’m joining a team of hard-working and innovative professionals and I share their dedication to providing superior products and services.”

James Russell Bruner

Director

James Russell Bruner was Chief Executive Officer and President of Maersk Line, Limited (MLL) from 2014 to 2017. Headquartered in Virginia, MLL is part of the global shipping consortium Maersk Group and provides U.S. flag transportation, ship management and maritime technical services to government and commercial customers.

Mr. Bruner joined Maersk Group in 1989 and has held various leadership positions in both North and South America. Prior to his role as CEO and President of MLL, he served as CEO and President of Maersk Inc., and President of Maersk South America Ltd. He also currently serves as a Director of MLL. A native of Baltimore, Maryland, Mr. Bruner attended Bridgewater College in Virginia. He is a graduate of the University of Michigan Executive Program and Harvard Business School’s Advanced Management Program. He serves on the Bridgewater College Board of Trustees, and previously served for the University of Denver Intermodal Transportation Institute’s Board of Directors.

I am impressed with the leadership team at Smith-Midland. The executives are truly committed to excellence. Safety, innovation and quality are the focus of all employees. I believe the future is bright for the Smith-Midland team.

Richard Gerhardt

Director

A veteran corporate executive in the shipping and logistics industry, Richard Gerhardt’s experience provides a wealth of successful business acumen to complement the board. He is the currently the Chief Sales Officer for IMEX Global Solutions and is serving his second term as a Fauquier County Supervisor for the Cedar Run Magisterial District. Richard serves on the boards of PATH Foundation and the Virginia Gold Cup Association.

From 2003-2014, he held an escalating succession of positions for three global shipping and logistic companies: DHL Global Mail, ESI Global Logistic and MSI Worldwide, including eight years as President/COO of MSI Worldwide. His leadership of MSI Worldwide culminated in the successful sale of the company to Belgian Post. Richard holds a bachelor’s degree from Washington College in Chestertown, Maryland.

“This is a unique organization. They are a long-term family business, and they treat their employees like family. But at the same time, there is a culture of quality and innovation and attention to detail that drives their success. It’s a winning combination.”

Ed Broenniman

Advisor

Ed Broenniman has been an advisor to Smith-Midland Corporation (DE) since 1992. He has 30 years of management and executive experience with high-tech, public and privately held growth companies where he has served as a CEO, COO, or Director, using his expertise to focus management on increasing profitability, strategic planning and building stockholder value.

He is the Managing Director of The Piedmont Group LLC, a corporate advisory firm, where he has built and sold four technology companies. In addition to his role with Smith-Midland, Ed serves on the Board of Aethlon Medical (AEMD), where he is Chairman of the Compensation Committee and a member of the Audit Committee. He is also on the Board of two privately held IT firms and has served on public company boards as well as venture-backed firms. He is the Chairman of the National Capital Chapter, National Association of Corporate Directors. He was the first Entrepreneur in Residence at the Dingman Center University of Maryland.

Matthew I. Smith

Director

Matthew Smith has served as the Vice President of Sales and Marketing since 2008 and President of Concrete Safety Systems since 2015, after working as the company’s Utility Sales Manager the preceding nine years. He also worked as the Sales Manager for Smith-Carolina from 1990-1993.

Matthew is active in the local community, serving as a member of the Board of Directors for Leadership Fauquier and as chairman of the Annual Remington Fall Festival since 2020. He is a past chairman of the Fauquier County Transportation Committee and past president of the Southern Fauquier Business Owners Association. Matthew is a Fauquier County Planning Commissioner and is active with the Midland Church of the Brethren. He is also a past president and current board member of the Precast Concrete Association of Virginia. He has a bachelor’s degree in business administration from Bridgewater College, where he serves on the President’s Advisory Council and is a past national chair of the Bridgewater Fund Committee.

“A hallmark of Smith-Midland has always been our commitment to producing high quality products backed with a high level of service. Today, we are still as committed to those standards as ever.”

Arthur X. Miles

Advisor

Art Miles joined Easi-Set Worldwide in 2013 as President and retired in January 2025. His successful tenure oversaw the expansion of Easi-Set licensing sales and the ongoing development of its proprietary product lines. Art previously served as the President and CEO of the Selimax Corporation, a management and technical consulting firm with a client base of Fortune 500 global companies in the steel manufacturing and construction industries. Before taking the helm at Selimax, he led Atlas Machine and Iron Works Inc., serving as president of one of the premier steel manufacturing companies in the United States. He is a graduate of Florida Southern College, where he earned a bachelor’s degree in Business.

“What makes Smith-Midland special? It’s the passion for what we do and the service we provide for our customers.”

Roderick Smith

Advisor

Since 2014, Mr. Roderick Smith has led the continued expansion and growth of the Smith-Carolina division as general manager of the plant in Reidsville, North Carolina. Under his direction, the corporation has completed a large expansion on a new site which sets the stage for future growth. Roderick’s many years working in the precast and real estate investment industries has proven highly beneficial to the corporation. Before joining Smith-Carolina he worked at the Midland, Virginia plant as a Steel Shop Manager, Batch Plant Manager, and in sales and production, giving him a well-rounded knowledge of the business.

Roderick holds several certifications including: NCDOT Field and Batch certification; ACI Field certification; and NPCA Master Precaster. He is involved in his local community and active with the Reedy Fork Community Church. Roderick attended Northern Virginia Community and Bridgewater Colleges.

“We take pride in producing quality products, and in being fair and honest. If we say we’re going to do something, we go out of our way to make sure it happens. We’re always working to get better and better.”

Ashley B. Smith

President & CEO

Ashley Smith is the current President/CEO of the parent corporation and President/COO of Smith-Midland (VA). Previously he served as Vice President of Sales for Smith-Midland (VA) and Managing Director of Easi-Set Industries. He has also served as Vice President of Smith-Midland Corporation (DE) since 1990 and as a Director since 1994. He was named President/COO in 2008 and President/CEO in 2019. As the CEO, he provides strategic vision for the company, while serving as a member of the Board of Directors. Ashley is a past chairman of the National Precast Concrete Association, is a current member of the Board of Trustees of Bridgewater College. He serves as a volunteer leader with many civic, educational and charity organizations.

“Our goal is to develop our Associates to their fullest potential, so they can contribute to their families, to society, and specifically in our company, to produce innovative, high quality, safe and cost-effective products for our customers. For our shareholders, the better we are at these initiatives, the better the results for their investment in Smith-Midland.”

Matthew I. Smith

Vice President of Sales & Marketing, President of Concrete Safety Systems

Matthew Smith has served as the Vice President of Sales and Marketing since 2008 and President of Concrete Safety Systems since 2015, after working as the company’s Utility Sales Manager the preceding nine years. He also worked as the Sales Manager for Smith-Carolina from 1990-1993.

Matthew is active in the local community, serving as a member of the Board of Directors for Leadership Fauquier and as chairman of the Annual Remington Fall Festival since 2020. He is a past chairman of the Fauquier County Transportation Committee and past president of the Southern Fauquier Business Owners Association. Matthew is a Fauquier County Planning Commissioner and is active with the Midland Church of the Brethren. He is also a past president and current board member of the Precast Concrete Association of Virginia. He has a bachelor’s degree in business administration from Bridgewater College, where he serves on the President’s Advisory Council and is a past national chair of the Bridgewater Fund Committee.

“A hallmark of Smith-Midland has always been our commitment to producing high quality products backed with a high level of service. Today, we are still as committed to those standards as ever.”

Dominic L. Hunter

Chief Financial Officer

Dominic brings over 20 years of financial leadership experience to Smith-Midland, with a strong track record in strategic financial planning and operational excellence across a wide range of organizations—including a multinational public company, privately held firms, non-profits, and startups. His executive experience includes leadership as Vice President at SRA International, a $1.7B publicly traded government contractor in Fairfax, VA. His deep manufacturing acumen led multi-year growth as CFO of O’Gara-Hess & Eisenhardt Armoring Company, a U.S. military contractor with a rich history that includes manufacturing armored vehicles for Presidents Kennedy, Reagan, Clinton and Bush, the Department of Defense and the Department of State. He is a graduate of the University of Virginia McIntire School of Commerce and holds an active license as a Certified Public Accountant.

“I look forward to partnering with the talented team to build upon the company’s long-standing legacy and strong foundation. Together we will work to unlock new growth opportunities, accelerate financial performance, and drive continued value creation for our customers, employees and shareholders.”

“A hallmark of Smith-Midland has always been our commitment to producing high quality products backed with a high level of service. Today, we are still as committed to those standards as ever.”

Steve Demas

Vice President of Project Management

Steve Demas brings more than 35 years of construction industry experience to his multiple roles at Smith-Midland Corporation. Early in his career he worked for Smith-Midland as a project manager, followed by stints with other well-known industry leaders Tindall Corporation and Shockey Precast. Steve returned to Smith-Midland in 2011 and has been in his current position since 2014.

Steve’s decades of precast concrete design, construction and project management knowledge along with expertise in lean manufacturing helps keep Smith-Midland on the leading edge of the industry. He has successfully managed more than 250 architectural, structural and design build/assist projects over the years.

Steve has a bachelor’s degree in Architecture and Urban Design from Hampton University in Hampton, Virginia, and a Class A Contracting license.

“We’re always striving for continuous improvement, not just in manufacturing but in our output to the customer. We listen to comments from the other trades that interface with our system and we bring those comments back and incorporate them into our designs.”

Ali Shahid, P.E.

Vice President of Engineering

Ali Shahid draws on vast experience in both domestic and international markets as the Vice President of Engineering at Smith-Midland Corp. After graduating from Rice University with a master’s degree in Engineering in 1984, Ali joined Western American Concrete, a precast company in Waco, Texas.

He later joined Redco International, a leading industrial manufacturing and contracting group based in Qatar and worked there for several years before returning to the U.S. and transitioning into the consulting business, where he worked with Pennoni, a multi-disciplinary consulting engineering firm with locations throughout the East Coast, focusing on civil and structural engineering and transportation.

After spending two decades with Pennoni and various other consulting firms, Ali’s career came full circle when he joined Universal Concrete Products in 2017, where he was head of structural engineering until joining Smith-Midland Corp. in January, 2021.

“I have seen the whole scenario, from being a precast engineer to being an Engineer of Record, where you are actually the person designing the building,” he said. Ali oversees design and documentation for both the architectural precast and utilities divisions at Smith-Midland Corp. He is also involved with ongoing research and development at the company.

“We are practicing Lean construction, studying ‘just-in-time’ scenarios and conducting labor studies to optimize the production side of things,” he said. “In addition, we are looking at research and development where we can implement more advanced technology that can enhance our product lines.”

“One thing I’ve seen compared to some of the other places I’ve worked is the diversity that we have here,” he said. “The mix of folks who are working here is very diverse, so that is definitely a breath of fresh air. The atmosphere is very congenial, which I think adds to the overall productivity of the company.”

Roderick Smith

General Manager, Smith-Midland – North Carolina

Since 2014, Mr. Roderick Smith has led the continued expansion and growth of the Smith-Carolina division as general manager of the plant in Reidsville, North Carolina. Under his direction, the corporation has completed a large expansion on a new site which sets the stage for future growth. Roderick’s many years working in the precast and real estate investment industries has proven highly beneficial to the corporation. Before joining Smith-Carolina he worked at the Midland, Virginia plant as a Steel Shop Manager, Batch Plant Manager, and in sales and production, giving him a well-rounded knowledge of the business.

Roderick holds several certifications including: NCDOT Field and Batch certification; ACI Field certification; and NPCA Master Precaster. He is involved in his local community and active with the Reedy Fork Community Church. Roderick attended Northern Virginia Community and Bridgewater Colleges.

“We take pride in producing quality products, and in being fair and honest. If we say we’re going to do something, we go out of our way to make sure it happens. We’re always working to get better and better.”

Ron Winkles

General Manager, Smith-Midland – South Carolina

As the general manager, Mr. Ron Winkles will oversee the continued expansion and growth of the Smith-Columbia plant.

With over 20 years of experience in manufacturing, engineering, and management, Ron brings with him a wealth of experience and knowledge to the industry.

Ron attended Georgia Institute of Technology.

“We want to be recognized as an organization that consistently delivers high quality, exceptional service, and value to our customers. It takes a team of dedicated, hard-working professionals striving every day to improve all aspects of the operation to achieve this.”