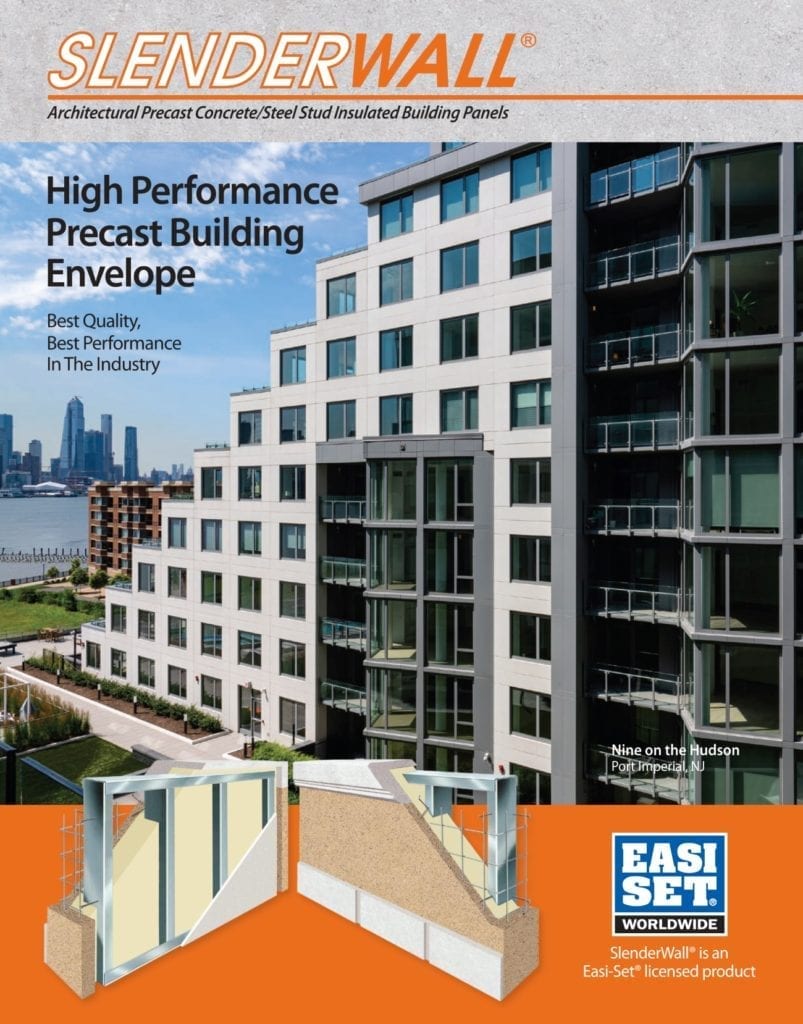

SlenderWall

Building Envelopes for the 22nd Century

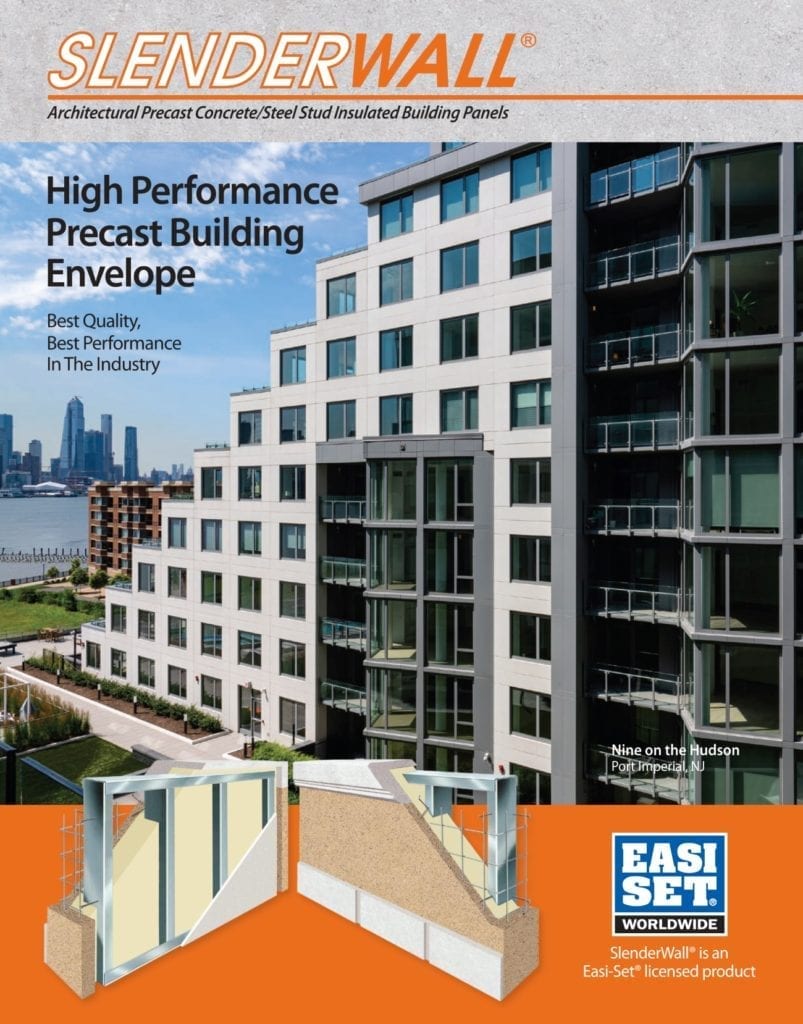

SlenderWall® Lightweight Precast Concrete Panel System

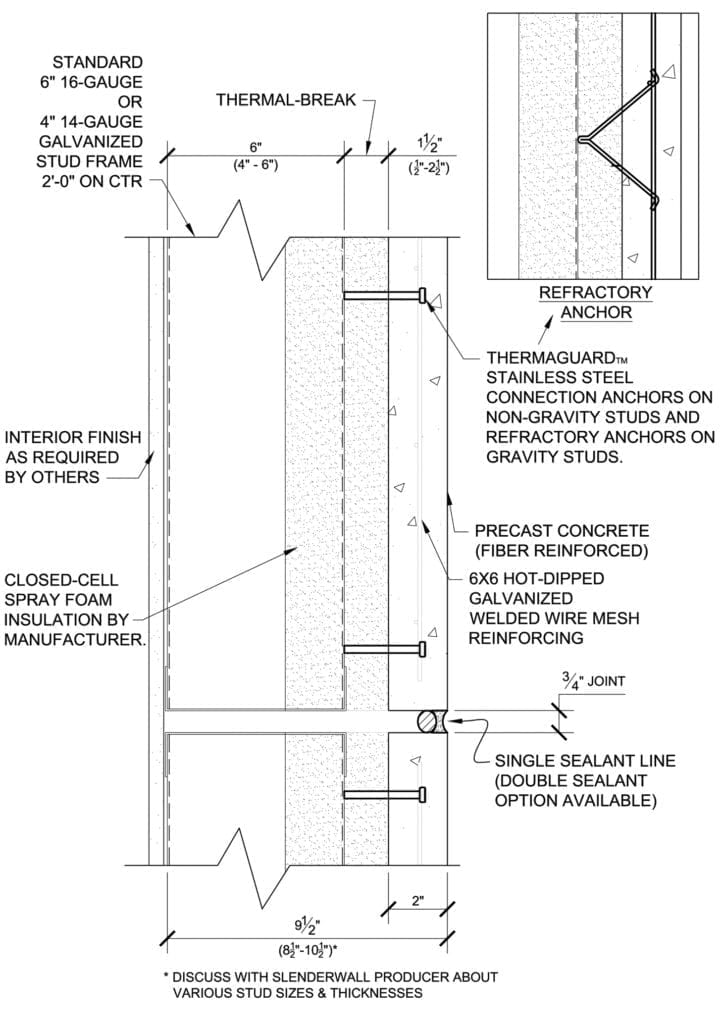

It’s the industry’s only precast concrete cladding system that does it all. SlenderWall incorporates the proven technologies of architectural precast concrete, high-tech PVA fiber and welded-wire reinforcement, stainless steel anchors and integral interior heavy-duty galvanized steel studs, and closed cell foam insulation. This dynamic precast concrete cladding system isolates the exterior cladding from the structural stresses associated with wind loading, steel frame movement, expansion and contraction, and seismic shock. Tough and long-lasting, expect your SlenderWall project to have both the style and durability to last into the 22nd century.

The architectural precast concrete cladding system by SlenderWall has benefits for everyone: the architect who designs the building, the owner and developer, and the residents who later inhabit it. Combining insulation, studs and vapor barrier into one lightweight panel reduces costs, cuts installation time and saves money. For projects that require 10,000 square feet or more of exterior cladding, SlenderWall is simply the best choice.

For a quick overview, watch our video

SlenderWall is designed with your primary needs in mind:

- Visual Impact

- Value

- Longevity

- Risk Mitigation

SlenderWall is the ideal system for all types of applications:

- New Construction

- Re-cladding

- Over-cladding

- Government/Institutional

- Medical/Hospitals

- Mixed Use

- Multi-family

- Office Buildings

- Parking Garages

- School Buildings

SlenderWall envelope panels can be designed to incorporate a wide range of building elements and styles:

- Spandrels

- Punch Windows

- Radius

- L-Shapes

- M-Shapes

- Custom Designs

Value You Can Measure

When it comes to architectural precast paneling, SlenderWall sets the bar for state-of-the-industry durability and ease of installation. But what differentiates SlenderWall’s proprietary panels from its competitors?

SlenderWall Architectural Precast/Steel Stud Building Panels provide:

- All the durability and versatility of traditional architectural precast, at 1/3 the weight

- A complete building panel, inside and out

- An integrated interior stud frame that reduces the construction schedule for on-site trades

- Less weight, which reduces perimeter foundation and superstructure costs

- Larger/lighter panels that speed erection schedules and reduce freight and crane costs

- Factory-applied closed-cell insulation that increases energy-efficiency

- Outboard-of-floor-edge mounting, which creates bonus square footage

- Fire Code Compliance

- Thermal Code Compliance

What is SlenderWall Architectural Cladding?

What is SlenderWall Architectural Cladding?

SlenderWall is a high-performance, thermal and fire code compliant, architectural panel system that combines proven technologies into a single efficient solution for new construction, re-cladding or over-cladding.

Part of what makes SlenderWall the benchmark against which other precast panels are measured are the technological benefits inherent in the system. SlenderWall’s extensive pedigree of engineered perfection makes it the leading choice for precast architectural cladding.

SlenderWall’s precast concrete cladding systems provide the lasting value that architects, general contractors and property owners/developers demand. Our exterior cladding system benefits are widespread, and it starts with durable and cost-efficient features. That’s why precast concrete wall panels by SlenderWall have been selected for projects across North America, with more than 4 million square feet of exterior cladding systems installed.

The value of SlenderWall shows itself throughout the design, delivery, installation and settling processes. Our precast concrete cladding systems are economical from the start with a focus on cost and quality – a major advantage with any precast concrete product. SlenderWall concrete panels are more than 66% lighter than traditional architectural precast concrete, which means expedited delivery, faster installation and lower costs for on-site labor.

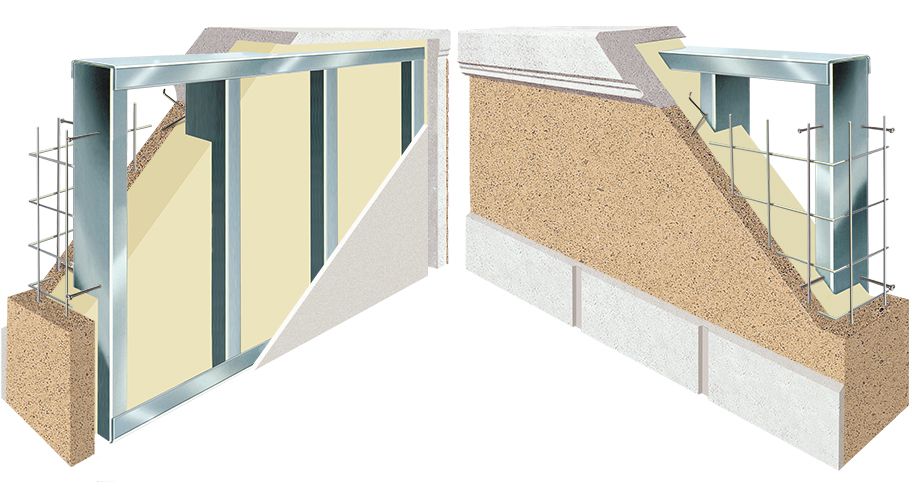

A Complete System, Inside and Out

A Complete System, Inside and Out

PRECAST CONCRETE

Thin-profile architectural precast concrete panel

G90 STUD FRAME

Integral galvanized steel stud frame, ready for drywall

THERMAGUARD

Variable-depth stainless steel connection system

2X REINFORCEMENT

PVA fiber and welded-wire reinforcement, engineered to last

CLOSED-CELL FOAM

Factory-installed continuous closed-cell foam insulation

FACTORY WINDOWS

Optional: Thermal windows installed and sealed in controlled conditions

LIFT & RELEASE

Optional: Exclusive panel-landing system designed for fast installation

H2OUT

Optional: In-the-joint rainscreen and leak detection sealant system

SECOND NATURE

Optional: Proprietary, custom and standard Class A finishes

Benefits of SlenderWall Precast Concrete Cladding

These architectural precast concrete panels reduce installation time and costs by up to 50%. Beyond a quicker and more cost-efficient installation process, SlenderWall concrete panels are also designed for a long life. The exterior cladding panels are maintenance-free and waterproof, and include an air space that creates a vapor barrier. Made from corrosion-proof and rust-proof materials, SlenderWall systems deliver long-lasting beauty to every building.

Each panel is manufactured in our climate-controlled facility, eliminating weather-related delays and significantly reducing on-site construction debris. Moreover, these lightweight precast concrete cladding panels reduce shipping costs by 60% as more panels can be delivered simultaneously. The flexibility that the SlenderWall system offers engineers and the money it saves contractors during installation is a win-win for both.

Why Use Lightweight Precast Concrete Panels for Building Envelopes?

Why Use Lightweight Precast Concrete Panels for Building Envelopes?

Precast concrete has become the architectural cladding material of choice wherever superior aesthetics and construction economy are decisive considerations. Lighter weight architectural precast composite panels combine the benefits of durability, low maintenance, excellent fire resistance and energy efficiency.

Versatility

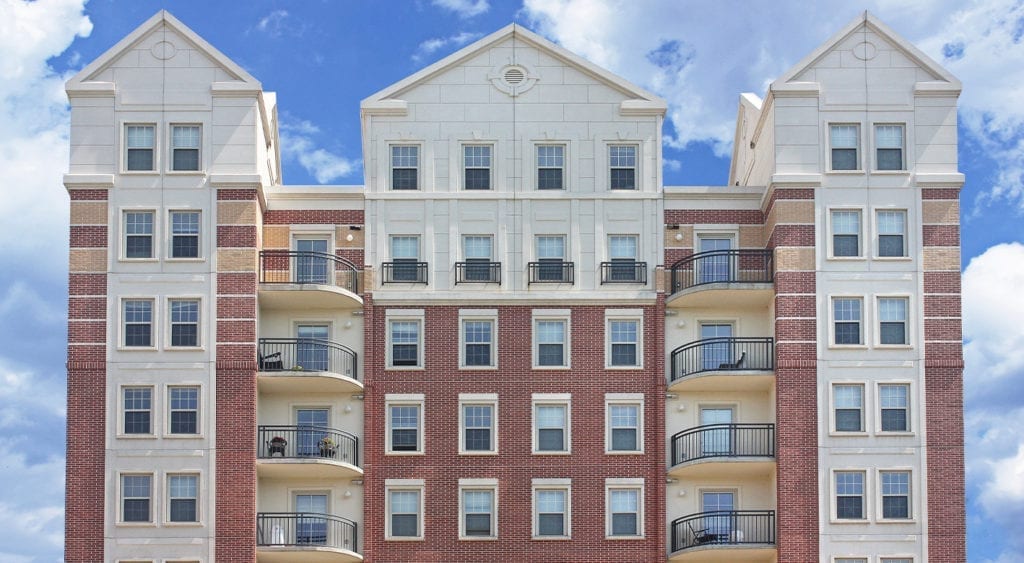

The true beauty of precast is found in the architectural effects that can be achieved. Custom-made forms are used to create panels in precise sizes and shapes. These forms introduce reveals, joints, patterns and other detailing to the panel surface. Specific color effects can be achieved by varying sands, aggregates, and pigments. Textures can be customized by using differing levels of sandblast and acid etch treatments. Stone, tile or brick veneers can be cast into the panels, giving architects a nearly unlimited palette of compelling visual effects.

Economical & Fast

SlenderWall panels are economical to produce, erect and maintain. Substantial cost savings can be achieved by taking full advantage of reduced foundation and structural requirements, shortened erection schedules and reduced labor from on-site trades.

Time-Tested Durability

Concrete has proven through the centuries to be the most reliable choice for building construction. Low maintenance and resistance to the effects of time, Mother Nature and human nature are the hallmarks of this material.

A True Value

SlenderWall combines the benefits of high durability, low maintenance, excellent fire resistance and energy efficiency. This creates an ideal solution for high-rise towers, where emphasis is on prestige, luxury, safety and aesthetic appeal, and lower-rise structures, where economy and durability are paramount.

Who Benefits?

Who Benefits?

Architects and Engineers – Superior Aesthetics and Versatility. Fully Tested Performance

- Appearance and Quality: Architectural precast concrete exterior finish

- Cost-Effective: Net cost to project is substantially below panel direct costs

- Flexibility: Large panels, cantilever applications, multiple finishes and design features

- A Proven Product: Fully tested by third-party labs and three decades in the field

General Contractors – Tighter Erection Schedules

- Reduced Construction Schedules: Large panels reduce the installation schedule

- Speed of Erection: Proprietary system increases installation rates by up to 50%

- Smaller Construction Cranes: Lightweight panels – 30 lbs/sf – enable use of smaller cranes

- Fewer Trades at the Site: Interior wall studs, factory-applied insulation and architectural finishes are cast into each panel, reducing the on-site labor required

Owners and Developers – Save money and time upfront and long-term with a product that lasts.

- Appearance: High-quality architectural precast concrete with integral architectural details and multiple finishes

- Lower Construction Costs: Reduced foundation and superstructure requirements, exterior wall framing integral to panel, shorter construction schedules, lighter cranes

- Added Space: Outboard mounting produces “bonus” square footage on every floor

- Cooling and Heating Costs: Panels have an integral thermal break/air barrier and code-compliant continuous insulation

- Permanence: Precast concrete finish, seismic isolation, superior caulking technology

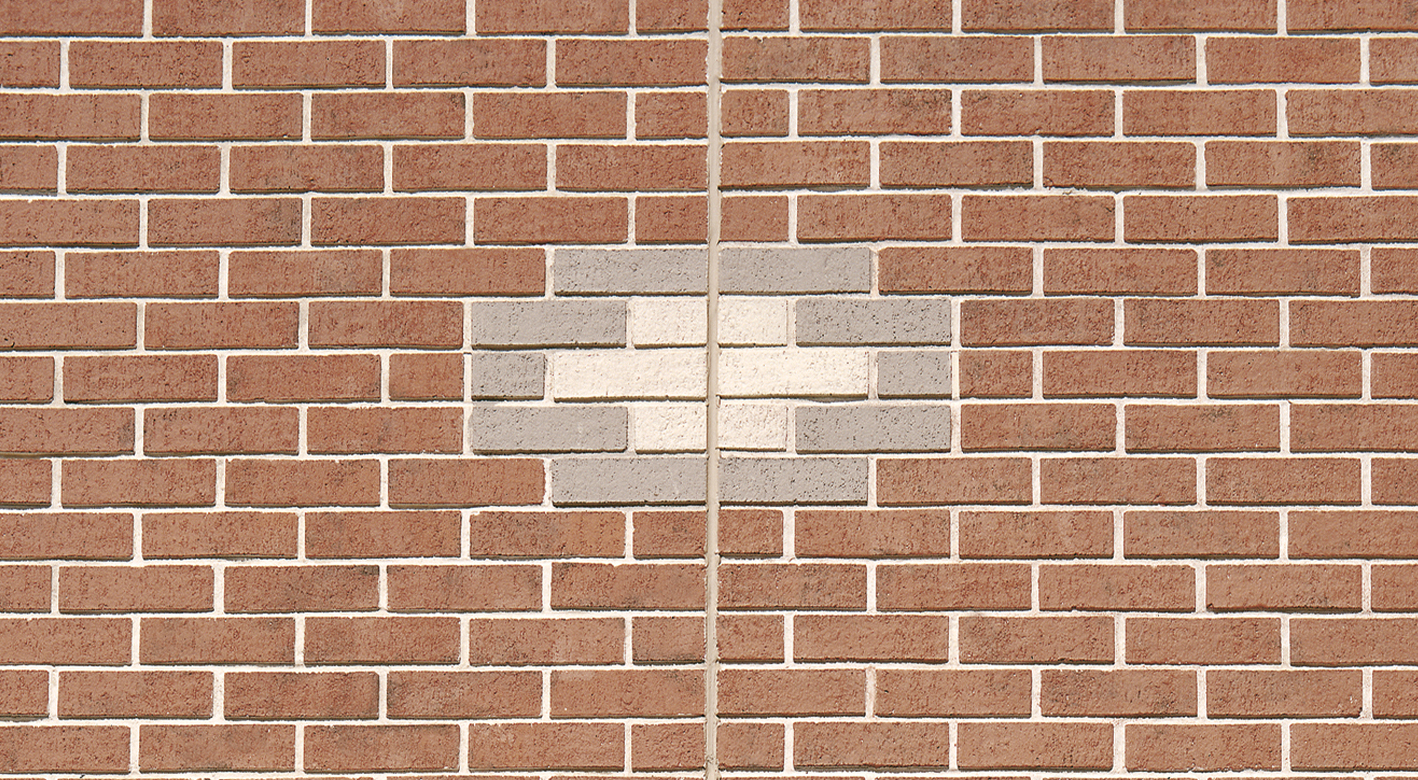

A Wide Variety of Architectural Precast Textures, Colors, Shapes and Finishes

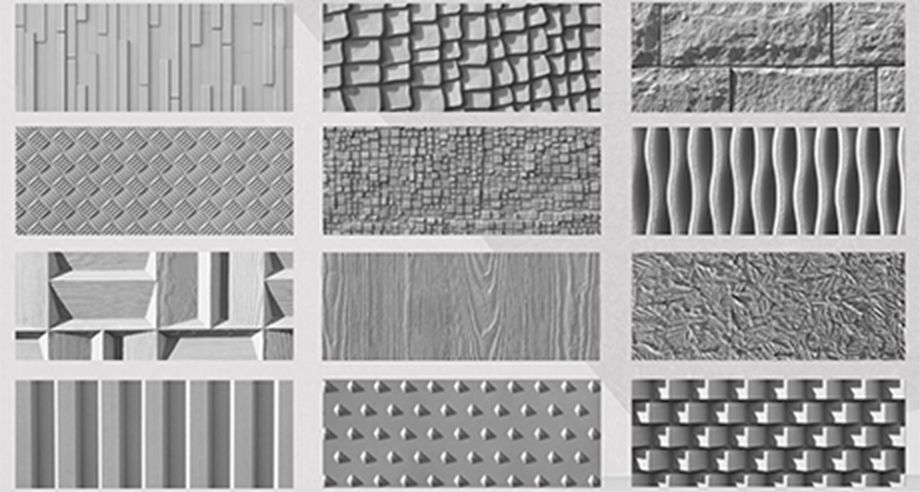

Design flexibility is achieved by choice of aggregate and cement color, size of aggregates, and finishing processes. Precast concrete can mimic a wide variety of man-made and natural finishes while providing long-lasting durability and cost efficiencies. Bump outs, reveals and detailing are limited only by the designer’s imagination, including multiple looks on the same panel. We can manufacture SlenderWall architectural precast panels in any color or texture featured in the PCI Color and Texture Guide. The guide features 24 color and 500 texture options. When the color and texture choices are combined with different color intensities, the architectural concrete finishes are virtually limitless. Multiple architectural concrete details, finishes, colors and formliner textures can be cast into every panel.

What’s Trending – Formliners and Photo Engraving

Surface textures, patterns and shapes can be achieved by casting with formliners. A large pattern plays with light and shadow. A fine texture offers subtle elegance. Dozens of unique patterns are available and innovative custom designs can be created using CAD and CNC technology. Photo-engraved formliners transform your façade into a canvas, with photos digitized for the CNC-cutter.

Integral Pigments and Surface Stains

Multiple colors can be applied to the concrete mix with pigments, or on the surface with new technologically advanced staining techniques. Even surfaces that mimic metal panels can be achieved.

109SB-M

111SB-L

147AE-M

363P

376AE-L

Buff Lime

611aSB-L

Reveals and Bumpouts

Sandblasting

Acid Etching

Concrete Stains and Color Pigments

Thin Brick

Second Nature Architectural Precast Brick

SlenderWall Cladding Design-Assist Services

Take advantage of our design-assist services to improve the efficiency of your building envelope project. Our in-house engineering/design team is comprised of experienced professionals who will listen to your needs and deliver a SlenderWall precast concrete envelope system that perfectly complements your project. By overlapping design, site work and pre-fabricated off-site manufacturing, our clients enjoy the cost savings and benefits of a shorter and smoother construction schedule.

Quality Control Standards

Quality control is at its highest possible level during the manufacturing process. Because all SlenderWall wall panels are produced in climate-controlled factories, outdoor temperature, snow, rain and heat do not alter the curing process. Smith-Midland facilities are nationally certified by PCI and NPCA.

Take a Quick Look Inside SlenderWall

How It’s Made

Proven materials and time-tested manufacturing methods create a durable and efficient composite panel.

Building the Frames

Creating the Forms

Mixing and Placing Concrete

Integrating the Frame

Insulating

Finishing

Fully Tested & Certified

Earthquake, hurricane and tornado-level testing establish SlenderWall as the system of choice for severe conditions. All tests were performed by certified independent laboratories using nationally recognized standards and methods. Detailed reports are available upon request.

- Fire (ASTM E119, NFPA 285)

- Seismic (AAMA 501.4)

- Structural (ASTM E330)

- Wind (226MPH, 130PSF, NOA #90101.05)

- Air (ASTM E283)

- Water (ASTM E331, AAMA 501.1, 503.3)

- Thermal (AAMA 501.5, 1503, ASTM C1363)

- Sound (ASTM E90)

- Blast (ARA-TR-10-000739)

Learn More About SlenderWall

Earn AIA credits and learn more about SlenderWall by reading our two current CEU courses.

Download Our SlenderWall Literature

Download Our SlenderWall Literature

Read “A Case for SlenderWall”, six case studies covering a wide range of market applications.

Request an Accredited Lunch & Learn for Your Organization

Anyone can offer you a free lunch. We’re offering you a look into the future.

Receive an accredited presentation and a free lunch. Qualifies for AIA learning units and HSW credit. SlenderWall combines time-tested materials: architectural precast concrete, stainless steel Nelson anchors and heavy gauge steel studs into a permanent lightweight exterior wall panel. Whether you are designing a new building or re-cladding an existing building, SlenderWall gives you the flexibility and the permanence of architectural precast concrete.

To sign up fill out the form below, call (540) 439-3266 or email us.

The Alexander, Edgewater, NJ

“We went to Virginia to study the panel system for a project in another state, and we were impressed by its capabilities. So, we decided to use the system again for the Alexander.”

Fred Daibe

Owner of Daibes Enterprises

Westin Hotel, Virginia Beach Town Center, Virginia Beach, VA

“SlenderWall was the right solution for us. This is the tallest building in Virginia, so we didn’t want to experiment.”

Lou Haddah, CEO & President

Armada Hoffler

Cleveland Clinic Holiday Inn, Cleveland, OH

“I can’t think of any hiccups, and I can’t think of anything I’d want to change. Any time you can just watch things go up as you expect, that works for me.”

Victor Famulari, R.A., NCARB

Smith-Palmer & Famulari, Ltd.

Johns Hopkins Hospital Nelson Harvey Building, Baltimore MD

“The design team strategized on how to address the exterior and make it completely weathertight and add sufficient insulation. It needed to be a lightweight system and it had to match the Johns Hopkins signature brick aesthetic on the campus, especially with its adjacency to the iconic Billings Building. The only product we found that met all our criteria was SlenderWall.”

Dan McKelvey, Associate Principal (and building envelope expert)

Ayers Saint Gross

Marriott Execustay, New York, NY

“I started the trend of using SlenderWall on high-rise buildings in New York City. I think that the SlenderWall system will be used on many buildings in New York in the future.”

H. Thomas O’Hara

H. Thomas O’Hara Architect, PLLC

BWI Corporate Center I, Linthicum, MD

“Curved panel applications are easily accommodated with SlenderWall. The combination of design choices, flexibility and cost savings has resulted in our choice of SlenderWall on several high-profile projects.”

Mitch Weber, Principal

Heffner & Weber

Huntington Hospital, Huntington, NY

“Our overall objectives of design flexibility, sound construction, and speed of building erection – all at economical costs – were made possible with the SlenderWall panel system.”

Tom LePage, Project Engineer

Barr & Barr

“SlenderWall provided the ability to be creative at an economical cost to the client. The flexibility of the system provided us with unlimited design freedom.”

Victor Famulari, R.A., NCARB

Smith-Palmer & Famulari, Ltd.

Seven Skyline Park, Falls Church, VA

“SlenderWall was the perfect solution for the penthouse panels. It weighs substantially less than 6” thick panels. We used the same mix as the base building panels for a perfect match.”

Andrew Rashid

Weihe Design Group

Woodlands I, Columbia, MD

“For this project, SlenderWall was cheaper, better and faster to install than alternative construction methods. After all of the options were evaluated, the obvious choice was SlenderWall.”

Mr. Doug Carter, AIA, NCARB

Davis, Carter, Scott

Rutgers – Health Insurance Plan Building, New Brunswick, NJ

“What attracted us to this product is the 2-inch thick precast concrete in an economical panelized format with steel-stud backup. This significantly reduced the cost of the structural frame and foundation required to support this much lighter system. Thus, we could achieve the beauty of a precast concrete or masonry exterior in a more cost-effective and efficient manner. Currently, we are on our fifth project using SlenderWall.”

Edward N. Rothe, FAIA

Rothe-Johnson-Fantacone Associates

Bradley Hall Building, Newark, NJ

“The SlenderWall panels were pre-insulated at the factory and were used to re-clad a deteriorated, turn-of-the-century industrial structure. The system installation integrated easily with the custom windows of our design. SlenderWall is a significant and permanent improvement to the existing building.”

Mr. Allen Trousdale

GRAD Associates

Woodlands II, Columbia, MD

“First, the system allows us to achieve our desired design of combined masonry and precast in one panel with significant savings over conventional brick veneer and precast. Secondly, we could construct a building with a masonry appearance in the dead of winter without cold weather delays and added costs for winterized construction.”

D. Ronald Brasher, Principal

D.R. Brasher, Architects

New Jerusalem Baptist Church, Queens, NY

“SlenderWall just makes sense. The SlenderWall system is the only product that can cost-effectively clad the building and provide the desired finish. SlenderWall is lightweight, easy to install, and keeps costs down — something we can’t get with any other product.”

Gary P. Santos, Architect

Ferguson Enterprises HQ3, Newport News, VA

“Our team especially wants to thank you for the great work that Smith Midland and EE Marr did for this project. From submittals to delivery and install, everything was smooth and timely and we look forward to working with you again in the near future.”

Gary Franks, Senior Project Superintendent

W. M. Jordan Company