Smithsonian National Zoo

Project Details

- Location

- Washington, D.C.

- Owner

- Smithsonian National Zoological Park

- Contractor

- Hensel Phelps and Athena Construction Group

- General

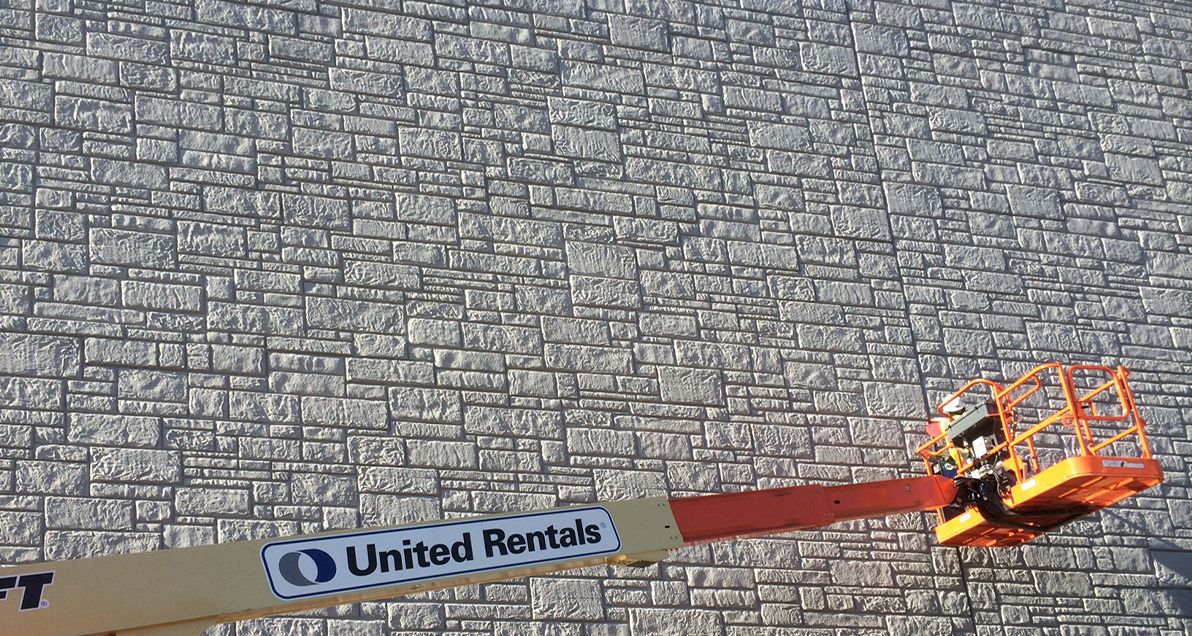

- 850 foot long x 30 foot high simulated stone retaining wall

- Quote

“You have a better looking wall this way. The joints all lined up well and the shoulder joints are set consistently. Speed of construction was good. The owner is pretty happy.” Kim Slusher, Hensel Phelps

- Awards

- AGC of DC Design-Build Subcontractor of the Year. Washington Building Congress Precast Concrete Project of the Year

A Design-Build Partnership at Smithsonian National Zoological Park

With an original design in hand for a cast-in-place wall at the Smithsonian National Zoological Park in Washington, D.C., the general contractor took a fresh look and settled on precast concrete. GC Hensel Phelps considered a few of the benefits of precast versus on-site construction – speed, less disruption at the site, less on-site labor needed, and, of course, aesthetics – and proposed a design-build partnership for the 850-foot long x 30-foot high simulated stone retaining wall. The wall would replace existing structures along an extensive drop off along the entrance road above parking lot C.

Enter Smith-Midland, partnering with contractors Hensel Phelps and Athena Construction Group to manufacture the precast concrete panels, and M & J Welding to complete the welding and wall erection. The new game plan involved the use of a shotcrete wall, with placement of precast concrete panels as a facing.

The panels were formed and hand-stained to mimic the look and color variations of a natural stone wall, based on the stone wall nearby on the Rock Creek Parkway. SMC prepared a mock-up of a wall section and delivered it to the National Zoo prior to production to serve as a proof of design for what was to be accomplished.

“This wall has all the color variations of a natural wall and is a permanent penetrating stain that will last indefinitely,” said Ashley Smith, President of Smith-Midland Corporation. “We are proud of this project that exemplifies Smith-Midland’s ability to innovate, improve and initiate products that are current and pleasing to the eye. We worked out the logistics with multiple contractors on this project and delivered a quality product for our customer.”

Panels were erected using a crane and were connected to the shotcrete wall with stainless steel plates and anchors. The erectors set seven panels per shift, a rate of about one panel per hour. Installation went quickly. Within a few weeks, a majority of the 30-foot high wall was completed. Hensel Phelps’ site manager, Kim Slusher, said the benefits of completing the project through design-build with precast were profound, compared to the original cast-in-place concept. “You have a better-looking wall this way,” Slusher said. “The joints all lined up well and the shoulder joints are set consistently. Speed of construction was good. The owner is pretty happy.”