Smith-Midland takes 1st and 3rd in 2020 NPCA Best Practices Awards

March 18, 2020 | Associate / Plant News

The National Precast Concrete Association announced the winners of their annual Best Practices Awards during the National Convention in Fort Worth, TX on March 5th. Both of Smith-Midland’s program entries won, garnering the Top prize and 3rd place.

William Garcia, Team Leader in the Steel Reinforcing Shop accepts the 1st place prize for Smith-Midland

NPCA’s Engineering & Technology Committee voted for Best practices innovations on the production floor. The award recognizes industry best practices and improvements that showcase the best way to do a job, treat the environment, save money, and more.

The judges noted about Smith-Midland’ entries, “really liked how your best practices contribute to inventory efficiency and effective employee communication.”

William Garcia, Team Leader in the Steel Reinforcing Shop, and Ernesto Ambrosio, Welding Shop Supervisor accepted the awards for Smith-Midland.

Ernesto Ambrosio, Welding Shop Supervisor accepts the 3rd place prize for Smith-Midland

1st place – Kanban Implementation: Kanban is a Japanese manufacturing system in which the supply of components is regulated through the use of an instruction card sent along the production line.

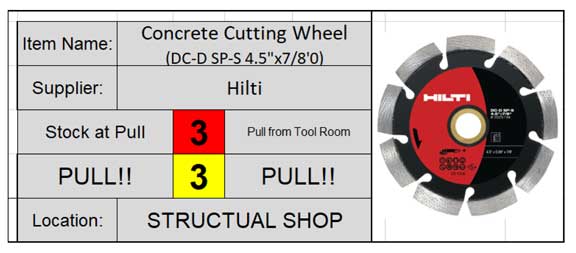

Example of a Kanban Card

A common problem in manufacturing is running out of needed materials, therefore affecting productivity. In addition, overstocking inventory burdens storage space and capital, and the occurrence of waste due to expired product shelf life is higher. The goal of adapting a Kanban System is to always have the material needed for production where and when it is needed.

The Kanban System Pull Cards are used at the point of consumption to maintain the minimum level without ever running out. When an item reaches the stock at pull number, the card is pulled and placed in a mailbox near the different production areas. These cards will be picked up by the water spider, a specific person whose main job is to supply materials.

The benefits of implementing a Kanban System at Smith-Midland have included:

- A visual system easily understood

- Employees can focus on work, not inventory levels

- Reducing the probability of running out of needed materials

- Reduction in inventory, material is ordered based on consumption and lead time

- Organization, efficiency and standardization, material delivery at set intervals

3rd place – WhatsApp Lean Chat: One important aspect of Lean Manufacturing is Continuous Improvement (CI). CI is the ongoing improvement of products, services or processes through incremental and breakthrough improvements.

One of the keys to implementing CI within a company is to build a CI culture. This can be challenging because associates are normally focused on their day-to-day responsibilities and do not want to spend time working on new “initiatives” such as CI.

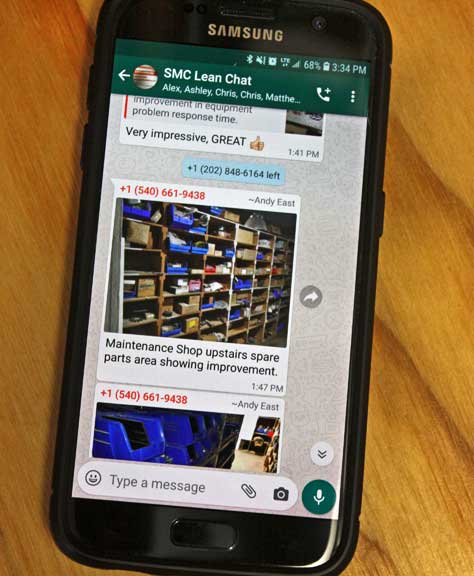

Smith-Midland’s WhatsApp Feed

In September 2018, Smith-Midland decided to create “SMC Lean Chat” on WhatsApp so that associates throughout the companies can share improvement videos with one another. Associates are encouraged to download WhatsApp on their phones, to make short videos of their improvements and upload them to SMC Lean Chat. This allows everyone to share improvements, motivate one another to do a better job, track improvements, increase morale and foster a CI culture within the company.

As a result of SMC Lean Chat, our associates are getting excited about sharing their improvement videos with others. The videos have encouraged others to make improvements and share their videos. It has motivated others to do a better job and has increased morale for those in the SMC Lean Chat. Improved quality and reduced labor in some processes have been made because of these videos. We are currently making an effort to get everyone who works at the Smith-Midland Companies on SMC Lean Chat to help spread a Continuous Improvement culture throughout the entire company, and more recently to the world on our new SmithMidlandLean Youtube channel.

The benefits of implementing the WhatsApp Lean Chat at Smith-Midland have included:

- Building a culture of Continuous Improvement company-wide

- Encouraging each other to make improvements

- A tracking system for improvements

- Increased associate morale and reduced turnover

- Lowered costs and increased productivity

Smith-Midland’s commitment to a Lean Manufacturing culture continues to foster improvements in both the lives of our associates and the value we pass onto our customers.

Thank you NPCA for your recognition of our efforts!